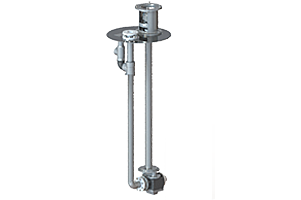

Our GS range is a vertical gear pump, an orientation simply to save space, or to submerge the gear pump in a tank of fluid.

If the pump is submerged into the fluid, it is often known as a column pump. A motor is generally mounted on top of a tank, and the pump is underneath in the fluid. A column is used to separate the pump from the motor, of a length depending on the requirements of the system. The advantages of this arrangement are:

- There are no problems with leaks

- Space saving

- Real flooded suction – minimise NPSH issues

- For pumping fluids at high temperatures, the pump stays at fluid temperature and does not need any insulation. This type of arrangement is common for bitumen.

- If desired, more than one pump can be put onto a shaft. This might be done to create two fluid supplies with different flow and pressure characteristics.

This is a highly customisable range, as we can supply a wide range of pumps on a choice of mounting plates with columns in different lengths and styles. Customers can specify the mounting plate, column length and pump choice to meet the requirements of their application.

The ability to submerge the pump in the fluid is popular in various industries including bitumen and liquid sulphur. Grease is available for intermediate bearings as required. We also make stainless steel pumps for solvent applications.

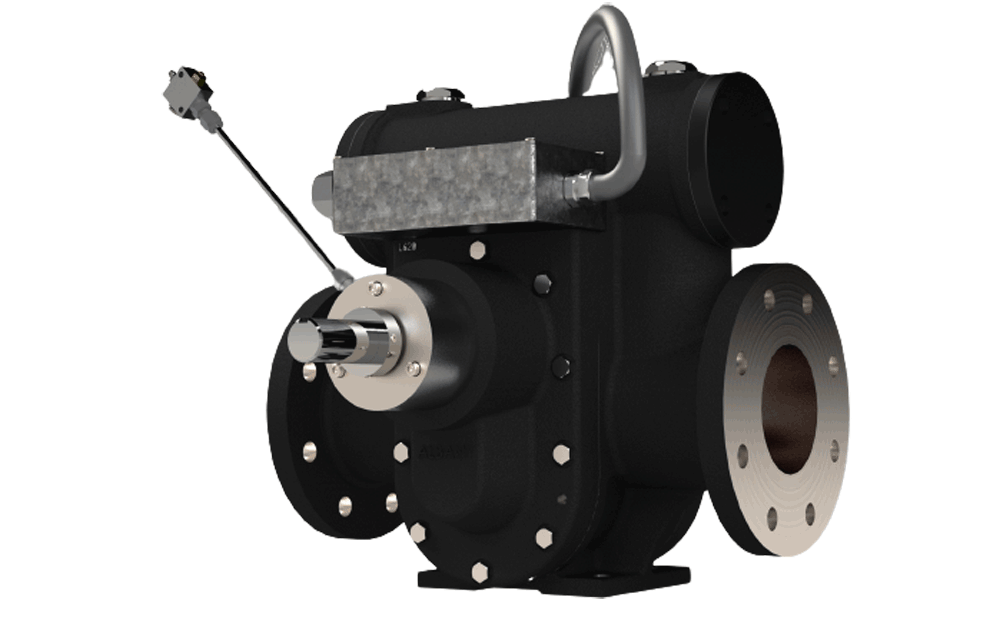

This S style pump fits to a variety of industries from Bitumen to Food and even Fire because of its highly adaptable nature.

- 15 barg maximum working pressure

- Pump size range 1/2" to 3"

- Maximum temperature of 200 degrees Celsius

- Flow rate up to 1400 L/min

- Available in a wide range of materials

- Column length up to four metres

- Choice of mounting plate design

- Wide range of material choices